Our State-of-the-Art Plant

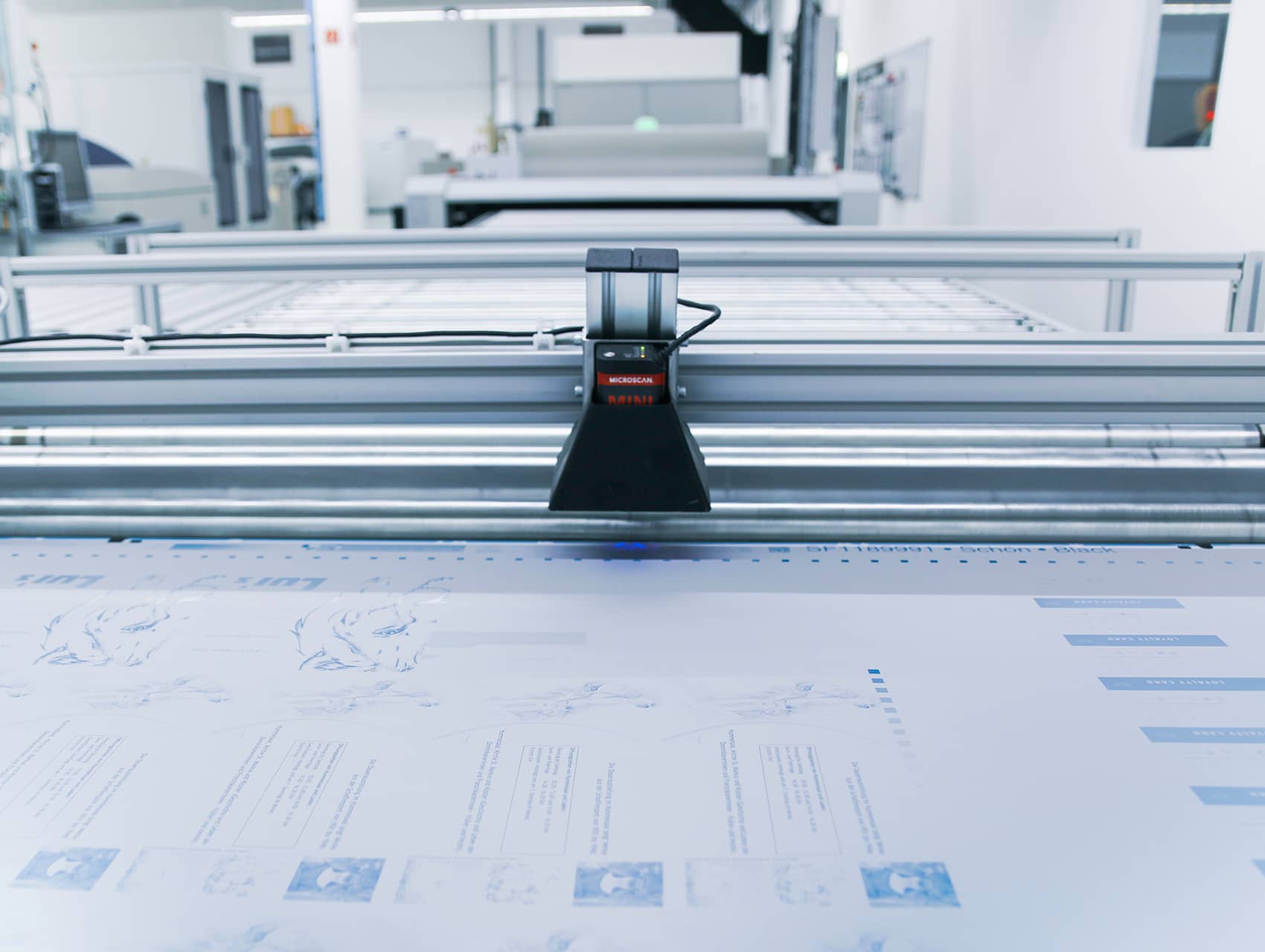

Print quality is our number one priority throughout the whole printing process. We always use the best materials and the latest printing technology. To meet our high demands for quality and efficiency, we use a combination of sheet-fed and web offset printing as well as digital printing.

We are pleased to offer you a glimpse into our efficient and ultra-modern production plant, which we have been investing in for over 25 years, to offer you the best possible print result.

The highlights of our machinery

Thanks to our Fujifilm and Kodak thermal platesetters we work with process-free printing plates and without chemicals.

At 6,000 sheets per hour, the HP Indigo 100K enables unprecedented productivity while delivering the highest Indigo image quality.

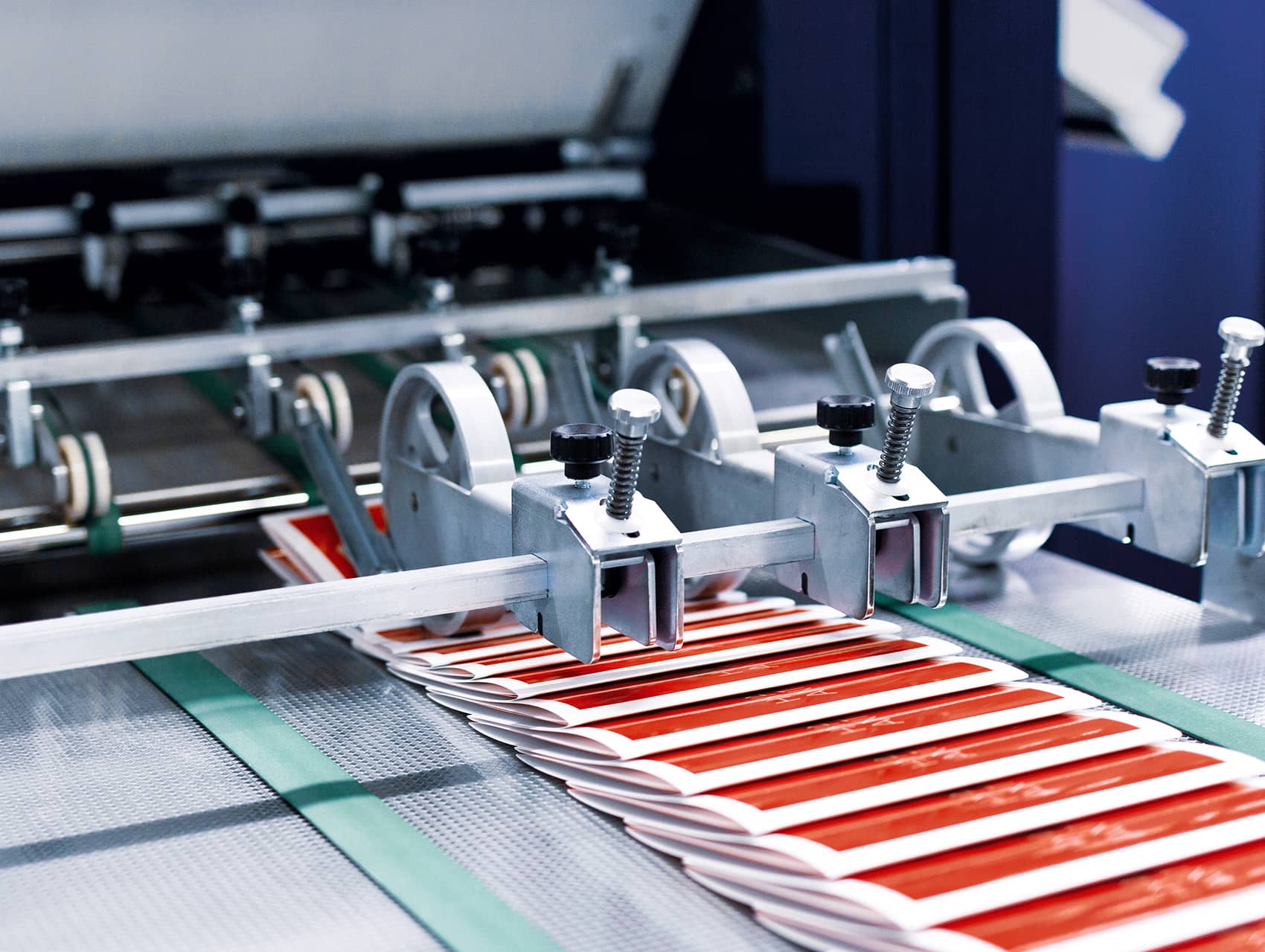

With our new Polar Die Cutter, we bring your business cards into shape quickly and to a high standard.

The new Heidelberg Speedmaster XL 106 offset press with sheeter and automatic plate changer can print up to 21,000 sheets per hour.

With the ultra-modern folding machine, Heidelberg Stahlfolder TH 82-P, we can produce up to 16,000 folded leaflets per hour.

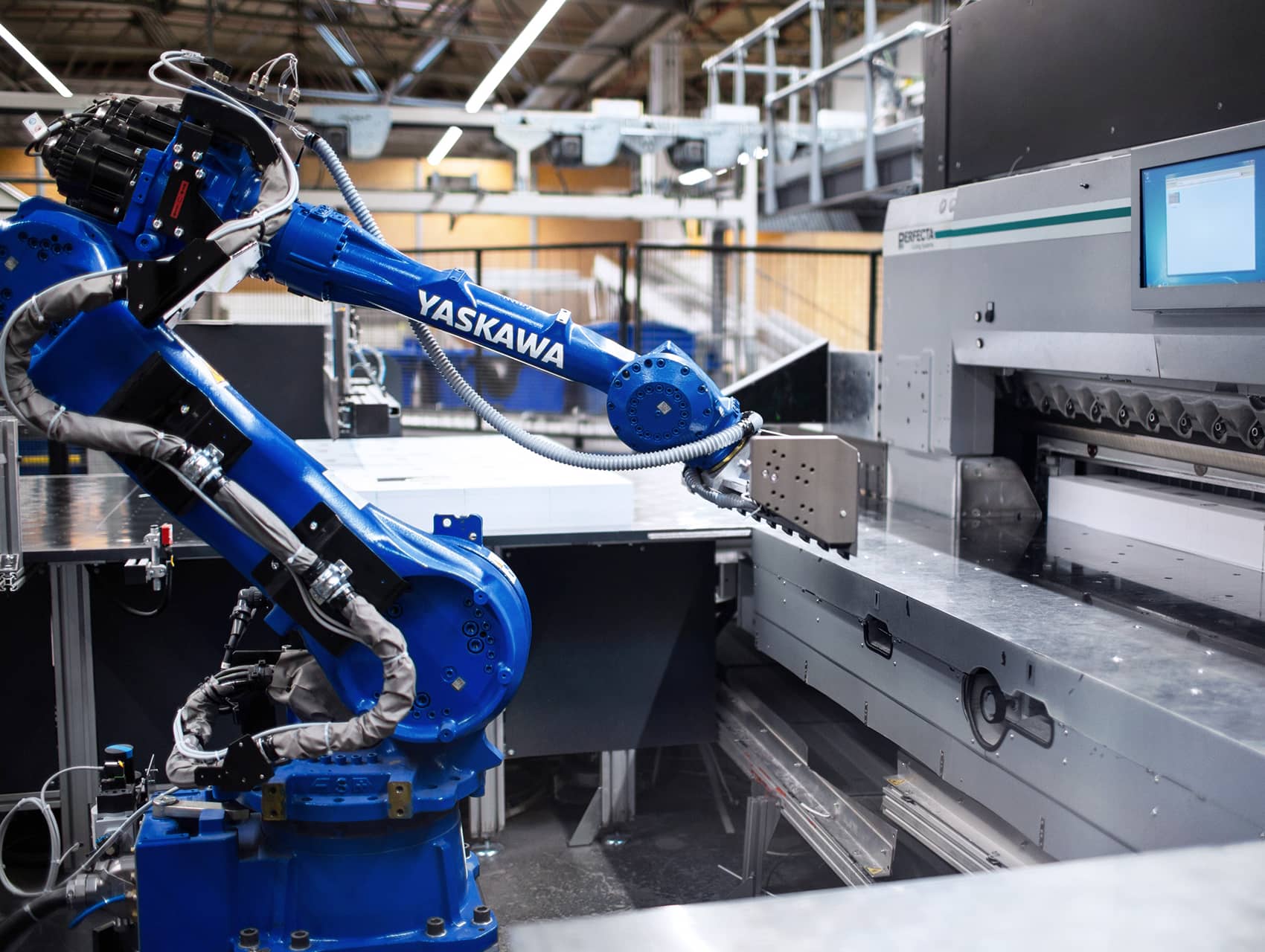

Our high-speed cutting machines such as this Perfecta 225 TS-LM in combination with our innovative cutting robot enable the highest precision when cutting your flyers.

With the fully automatic high-speed punching and binding Renz Inline 500 machine, we can provide spiral binding for up to 2,000 calendars per hour.

Our perfect binding line consists of the MG-600 by Horizon and five Heidelberg Stitchmaster ST450 to produce the perfect binding for your brochures.

The Autobond Mini 76 TPHS laminating machine and the Steinemann Colibri 74 UV coating machine provide high-quality finishing for your products.

Our Story

2024

With the takeover of the Large Format Printing production of EAST|print GmbH, advertising technology products such as roller banners, beach flags and exhibition counters can now be offered at even lower prices.

SAXOPRINT runs the world's fastest Heidelberg Speedmaster XL 106 perfecting press. 21,000 sheets per hour can be printed in optimum quality.

2021 - 2022

The path to fully automated printing plate logistics is further expanded: Thanks to our new Speedmaster-XL-106 8-P 18k press with Cutstar, the ‘Plate to Unit’ system was successfully installed in the existing printing process.

By automatically changing the printing plates and using the digital planning tool Prinect, the printing process is carried out as efficiently as possible. This enables SAXOPRINT to produce products even faster, more accurately and more cost-effectively.

2020

SAXOPRINT makes further investments in their production plant. For example, by acquiring a world-first in digital printing, the HP Indigo 100K and the new brochure binder, Horizon Perfect Binder BQ-480.

We take another step towards sustainability by transitioning to process-free platesetting, meaning we use fewer chemicals, water and electricity.

2019

With the 50m long Heidelberg Speedmaster XL 162 including the Cutstar sheeter, a world-first goes into operation at SAXOPRINT. It ensures efficiency and top quality.

2018

By buying the entire company site and integrating the Berlin-based print shop LASERLINE as a full subsidiary, SAXOPRINT provides long-term employment for many of its staff.

2015 - 2017

We offer new product lines and new business solutions to our customers, including the introduction of SAXOPRINT® pro design and SAXOPRINT® easy box. We launch our online shops in the Netherlands and Belgium.

2013 - 2014

SAXOPRINT reinvents itself with a website and logo redesign and invests large sums in new machinery. For the first time, the number of employees exceeds 500. Improvements to production processes are followed by a further expansion of the production area to over 18,000 m². We launch our online shop in Italy.

2008 - 2012

We open further online shops in France, Austria, Spain and Switzerland. Production capacities increase significantly with the acquisition of the first Heidelberg Speedmaster printing machine. SAXOPRINT gains a strong partner and becomes an independent subsidiary of CEWE Stiftung & Co. KGaA.

1999 - 2007

SAXOPRINT GmbH is founded as a small local digital & offset printing company with 22 employees in Dresden. We then open our first online shop for the German market, closely followed by the launch of our online shop for the United Kingdom the following year. The production area is expanded to 10,000m². More than 300 jobs are created in the process.